In product literature for sheet plastic, the terms acrylic and Plexiglass are frequently interchangeable. Even though Plexiglass is a form of Acrylic, minor variances are present depending on their application. If you are looking to buy acrylic sheets and other acrylic materials in Dubai, consider Pleasant Acrylic. They are currently the best suppliers of acrylic products in the UAE.

When it comes to the difference between Acrylic and Plexiglass they are relatively similar. However, there are a few distinctions. Let’s take a look at what Plexiglass and Acrylic are and their detailed comparison.

Table of Content

Acrylic

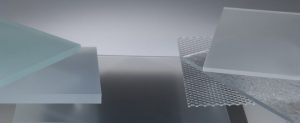

Acrylic is a strong, stiff, and optically clear transparent plastic with excellent strength and rigidity. Acrylic sheet is simple to produce, adheres well to adhesives and solvents, and thermoforms easily. Acrylic Glass outperforms several other transparent polymers when it comes to weathering. Acrylic has glass-like properties but is half the weight of glass and has higher impact resistance.

Acrylic plastic is a thermoplastic homopolymer that is transparent. To put it another way, it’s plastic—specifically, polymethyl methacrylate (PMMA). Though its primary function is in the form of sheets as an alternative to glass, we can also use it in casting resin models.

While glass is less expensive to buy and recycle than Acrylic, acrylic plastic is more durable, shatter-resistant, and resistant to external elements and erosion. According to a current study, Acrylic can be more scratch-resistant than glass or exceedingly scratch and impact-resistant, depending on its manufacture. In addition, acrylic glass offers exceptional versatility, impact strength, and aesthetic attributes. It includes everything from sturdy signage and skylights to eye-catching retail display store fixtures, displays, and other functions.

Manufacturing Of Acrylic

Manufacturers can make Acrylic Glass using two different methods. It’s either cell cast or extruded. Extrusion is a less expensive method of producing Acrylic, but it has two drawbacks. First, because extruded Acrylic is softer than cell cast acrylic, it is more easily scratched. Second, extruded Acrylic can also contain contaminants on the surface. Because of the casting process, cell cast acrylic has a more rigid surface. In addition, Acrylic Glass is created in a closed region when cell-cast, which lowers the likelihood of contaminants becoming trapped in the transparent material.

Plexiglass

Plexiglass is a late-nineteenth-century plastic substance. It’s translucent, impact-resistant, flexible, and robust, and we can use it in various industries, including the printing of 3D images. Acrylic Plexiglass is a type of plastic manufactured from methyl methacrylate. Polymethylmethacrylate, or PMMA for short, is the technical term for this substance. Plexiglass is its original and most well-known commercial name, but it also goes by various other names.

Due to its more robust environmental stability than most other plastics, such as polystyrene and polyethylene, it is also excellent for outdoor applications. For example, we can use Plexiglass as acrylic panels and acrylic roofing sheets outdoors. Plexiglass is a highly beneficial invention because of these advantages, as well as some additional features. These include a long service life, excellent UV light transmission, and ease of processing.

On the other hand, Acrylic Plexiglass products rarely use pure PMMA products, preferring to alter the material to improve its function even further. For example, adding butyl acrylate boosts impact strength, methacrylic acid enables higher temperature uses, dyes provide color for decorative purposes and many more adjustments.

Manufacturing Of Plexiglass

The manufacture of Plexiglass begins with the distillation of hydrocarbon fuels into lighter fractions, which then manufacturers mix with additional catalysts. The crackers that manufacture the basic building blocks for producing acrylic plexiglass need petrochemical feedstock from crude oil and natural gas. In general, it takes around two kilograms of petroleum feedstock to make one kilogram of PMMA.

Plexiglass has higher manufacturing expenses, which is visible in its higher price. Production of Plexiglass is frequently in sheets for use as a lightweight, shatter-resistant substitute for organic glass. We can easily mold it into various shapes, including tubes, rods, and an acrylic box.

Detailed Comparison Between Acrylic And Plexiglass

There are more similarities than differences between Plexiglass and acrylic sheeting. Therefore, the properties of plexiglass and acrylic items referred to as Plexiglass are usually reasonably comparable. There are, however, specific differences between Plexiglass and Acrylic, which we will see below.

◉ Differences In Manufacturing

Extrusion or cell casting are the two most common methods for producing acrylic sheeting. An extrusion method makes extruded Acrylic, as the name implies. Acrylic sheets are created by extruding Acrylic continuously.

However, in the cell cast technique, unreacted Acrylic is poured between two panes of resistance of glass to form a cell. The normal glass is detached from the standard acrylics sheet and inspected once the reaction sets. Cell cast acrylic is more expensive than other types of Acrylic since the process takes longer and requires more workforce, but it is usually of superior quality and lasts longer. Therefore, only the cell cast procedure can make plexiglass items.

◉ Differences in Fabrication

Surface hardness is the fundamental mechanical properties, which include differences between higher cost, as much as 25% more expensive (depending on the grade) significantly stronger, with 250x the impact resistance of glass and 30x the strength of acrylic transmits 88% of visible light working temperature of 240 degrees, giving it a low level of flammability Resists chips and cracking Corrosion resistant when used in chemical applications will not crack even when the plastic sheet is drilled in to Can be formed without heating. If you need bullet-resistant materials or lightweight material to use in a highly caustic environment, such as in a plant that works with acidic or other potent chemicals, then polycarbonate is probably the right fit.

Between extruded acrylic glass plates and Plexiglass. Because Plexiglass has a more rigid surface, cracking is a minor problem in comparison to Acrylic. In addition, chemicals, such as solvent cement used to glue Plexiglass together, are more scratch-resistant to the surface.

◉ Brands of Acrylic Or Trade Names

The various names used in the plastics business are the most perplexing aspect of Acrylic and Plexiglass. Acrylic is a generic term that refers to the type of polymer utilized in its production. However, people commonly refer to cell cast acrylic as Plexiglass.

If you ask for an Acrylic counterpart in a store, you might get whatever the store sells typically. However, you’ll gain the right stuff if you use the correct terminology and understand the differences between the two.

Conclusion

According to the detailed comparison among the differences between Plexiglass and Acrylic, you can see that both the materials are pretty similar. As a result, you can now make better plans on how you’ll employ each in the future.

Pleasant Acrylic is the best acrylic sheet supplier in Dubai that specializes in point-of-purchase displays. Pleasant Acrylic provides full-service product design, engineering, tooling, and plastics manufacturing. They also provide acrylic furniture, acrylic panels, acrylic roofing sheets, and Acrylic Bending, among others. You can also share your ideas with them to create a product that meets your needs. Their designers and engineers will create images and models of the product and prepare it for production.

The designers in this Acrylic Company in Dubai will create 3D images and models from the images you provide if necessary. They will create a larger image based on the original image. They will also create an accurate model with the accurate orientations and depths of the product you require. You can see how the product will look when they finish using 3D images and model comparison. You can select the optimal model from the reference model which they will provide. They will begin production once you approve the 3D images and models. You will receive the final product in usually three to four weeks from the start of production, depending on how the model appears and the quantity necessary.

Frequently Asked Questions

ⅰ. What is acrylic/plexiglass?

Acrylic drums are a strong, stiff, and optically clear transparent plastics industry with excellent strength and rigidity. Acrylic glass offers exceptional versatility, impact strength, and aesthetic attributes. Whereas, Plexiglass is a translucent, impact-resistant, flexible, and robust plastic material. We can use it in various industries, including the printing of 3D images.

ⅱ. What is Acrylic used for?

Acrylic castings are transparent plastic with a wide range of uses due to its ability to replace standard ordinary glass. Signs, sales displays, roof windows, lenses, and screens are among the daily objects that utilize it. But also for complex structures like undersea windows and flat-screen TVs using fiber optics for UV resistance.

ⅲ. How to cut acrylic sheets?

When it comes to cutting acrylic acrylics sheets for heat resistance, a jigsaw is one of the most used equipment. It’s a portable tool that can cut a sheet with a straight blade by function up and down quickly. Another precise method of cutting a specific design from an acrylic material is acrylic laser cutting. It entails a machine that emits a laser that burns or vaporizes the acrylic substance, cutting it through.

also read our blog post: 7 Tips for Working With Acrylic