Acrylic UV printing has revolutionized the printing industry with its ability to produce high-quality, durable prints on a wide range of surfaces. As we step into 2024, the landscape of this technology is rapidly evolving, bringing forward innovations that are set to redefine the standards of modern printing. This blog post explores the top trends in Acrylic UV Printing for 2024. We have also highlighted the latest advancements and their implications for the UV printing industry.

Table of Content

Acrylic UV Printing Industry Trends

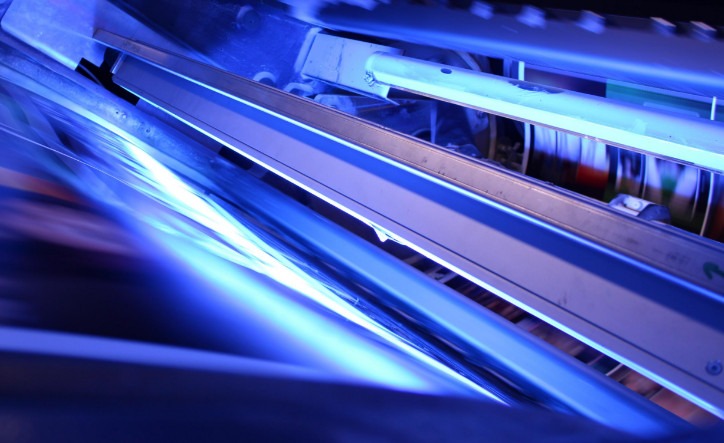

Acrylic UV printing is a modern printing technique that uses ultraviolet (UV) light to cure or dry the ink as it is printed directly onto acrylic surfaces. This method leverages UV-sensitive inks that solidify upon exposure to UV light, resulting in vibrant, durable, and high-quality prints. Acrylic UV printing utilizes ultraviolet light to cure or dry the ink as it is printed.

This technology ensures quick drying times, vibrant colors, and durable prints on a range of substrates that can withstand harsh environmental conditions. It has found applications across various industries, including advertising, interior design, and manufacturing, due to its versatility and superior quality. Additionally, these inks do not release volatile organic compounds (VOCs), making them safer for both human health and the environment. Let’s check the 2024 printing innovations.

1. Advanced UV LED Technology

One of the significant trends in acrylic UV printing is the adoption of advanced UV LED technology. Traditional UV lights are gradually being replaced by UV LED systems, which offer several advantages:

- Energy Efficiency: UV LED systems consume less power, reducing operational costs and making the process more environmentally friendly.

- Longer Lifespan: UV LEDs have a longer operational life compared to traditional UV lamps, leading to reduced maintenance and replacement costs.

- Instant On/Off: Unlike traditional lamps, UV LEDs do not require warm-up time, enhancing productivity and efficiency.

This shift towards cutting-edge technology is paving the way for more sustainable and cost-effective printing solutions in 2024 with a lasting impression.

2. Enhanced Print Resolution and Quality

As the demand for high-resolution prints continues to rise, manufacturers are focusing on improving the print resolution and quality of acrylic UV printers. The latest UV printing technology now supports ultra-high-resolution prints, enabling the production of intricate designs and fine details with remarkable clarity. Innovations in ink formulation and printhead technology are driving this trend, allowing for better colour accuracy, gradient transitions, and overall print sharpness.

3. Expanded Material Compatibility

Modern UV printing technology has expanded its compatibility with a variety of materials, beyond traditional substrates like acrylic and PVC. In 2024, we are witnessing UV printers capable of printing on unconventional materials such as wood, metal, glass, and even fabrics.

This versatility opens up new possibilities for creative applications and customization, catering to a broader range of industries and consumer needs. By combining printing inks like UV-curable ink with DTF powder, UV DTF printers can produce high-quality printing designs(vibrant images) on textiles without requiring a white ink layer. Expanding UV printing beyond traditional paper and glossy finish materials unlocks a world of creative possibilities for businesses and designers.

4. Eco-Friendly Printing Solutions

Sustainability is a major preferred choice across industries to minimise the environmental impact, and the modern UV printing sector is no exception. In 2024, there is a significant push towards eco-friendly printing solutions in the UV printing market. This includes the development of environmentally friendly inks from organic compounds that are free from hazardous chemicals and solvents. This involves choosing inks that don’t contain harmful chemicals. Additionally, the increased efficiency and reduced energy consumption of UV LED printers contribute to a lower carbon footprint, aligning with global sustainability goals.

5. Automation and Smart Printing

Automation is transforming the UV printing industry, making enhancing printing speed, more efficient, and less labour-intensive. The integration of smart technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) into UV printers is enabling real-time monitoring, predictive maintenance, and automated workflows. This trend not only enhances productivity but also ensures consistent print quality and reduces downtime. Ai will play a crucial role in the future trends of acrylic fabrication.

6. Customization and Personalization

The demand for customized and personalized products is on the rise, and UV Digital printing technology is well-suited to meet this trend. In 2024, we see an increasing number of businesses offering personalized printing services, from custom phone cases, and outdoor signage to bespoke interior decor. The ability to print on a range of materials with high precision makes UV printing an ideal solution for creating unique, one-of-a-kind products that cater to individual preferences.

7. Improved Durability and Outdoor Applications

The acrylic UV printing process is known for its durability, and the latest UV printing technologies are further enhancing this attribute. New ink formulations and curing processes are making prints more resistant to fading, scratching, and environmental wear and tear. Robust nature makes UV printing an excellent choice for outdoor applications, such as signage, vehicle wraps, promotional materials and outdoor displays, ensuring longevity and aesthetic appeal over time.

8. Integration with Digital Technologies

The integration of digital technologies with UV printing is another trend gaining momentum in 2024. Unlike traditional printing methods, it includes the use of digital design tools, cloud-based print management systems, and augmented reality (AR) for previewing designs. Such integrations streamline the design-to-print process, improve accuracy, and allow for seamless collaboration between designers and printers.

9. Cost-Effective Short Runs

One of the advantages of acrylic UV printing is its cost-effectiveness for short-run productions. In 2024, this advantage is being further amplified by advancements in print speed and efficiency. Businesses can now produce small batches of high-quality prints quickly and affordably, catering to the growing demand for on-demand printing and reducing the need for large inventory storage.

10. Innovative Applications and Market Expansion

As UV printing technology continues to evolve, new and innovative applications are emerging. From 3D printing enhancements to creating tactile textures and embossing effects, the possibilities are expanding. This trend is driving market expansion, with more conscious consumers recognizing the capability of UV printers for various applications. This innovative technology with a high commitment to quality is beneficial for industries from fashion and textiles to automotive and aerospace

also read: 10 Creative Ways to Use Acrylic Display Stands in Visual Merchandising .

Conclusion

Significant technological advancements and industry shifts mark the endless possibilities of acrylic UV printing landscape in 2024. These trends are shaping the future of UV printing, from the adoption of energy-efficient UV LED technology to the integration of smart and digital solutions. As businesses and consumers increasingly seek high-quality, sustainable, and customised printing solutions, the UV printing industry is poised to meet these demands with innovative and versatile technologies.

The scope of UV printing looks bright, with continued growth and innovation on the horizon. As we move forward, staying abreast of the competitive landscape will be crucial for businesses and professionals. In the printing industry leverage the full potential of modern UV printing technology and stay competitive in the evolving market.

Pleasant Acrylic specializes in the acrylic industry providing top-notch manufacturing and upholstery services in Dubai. They specialize in precision engineering and tooling through their Acrylic UV Printing Service in Dubai. As leading acrylic fabricators in Dubai, they offer high-quality products for a wide range of applications. Their expertise also extends to being reputable acrylic sheet suppliers in Dubai ensuring that all products meet the highest standards of sustainability and aesthetics.