Acrylic is well known for its incredible durability and high impact resistance properties. With the increased use of various acrylic products in the market, every acrylic company in Dubai has been highly engaged in ensuring that clients and customers are delivered with the best laser-cut acrylic products. Since acrylic material is shatterproof and an ideal alternative to glass, this transparent thermoplastic, chemically called polymethyl methacrylate, is best for precision machining. Acrylic is basically of two types: cast and extruded acrylic. The former is the best for the laser engraving process and made using a casting of resin of polymethyl methacrylate to a steel belt in motion, or to a mold, to obtain acrylic sheets. Whereas the extruded acrylic is produced with the techniques of forcing the resin in between steel dye set to generate a huge acrylic sheet, later cut to form separate sheets. This type of acrylic has a polished edge and is ideal to be used for the laser cutting process.

Table of Content

Acrylic Laser Cutting and Engraving

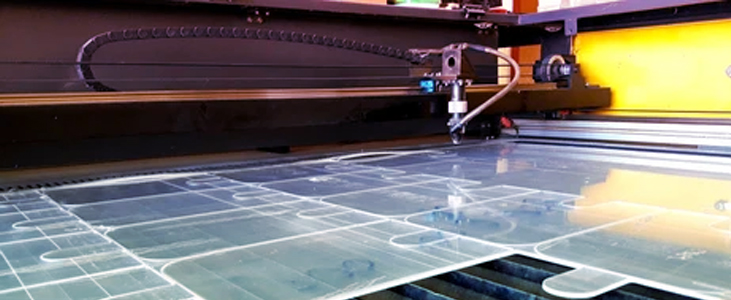

Acrylic Cutting and engraving involve utilizing a machine that can emit laser, thereby called laser cutting. The laser cutting can be easily made to cut through the acrylic material with vaporization and burning techniques. With the acrylic cutting and engraving techniques, you can cut out the desired acrylic material designs easily. Engraving is a process where various ranges of designs are produced on acrylic sheets, with a high-quality engraving machine that uses laser technology.

Nowadays, CAD files and 3D models can direct you to make the desired laser cutting projects better and guide you on them. Acrylic laser cutting in Dubai is famous for its digital subtractive creation procedure involving engraving or cutting a particular material utilizing a laser. This technique is useful for major businesses that produce a significant number of acrylic ideas and products. To ensure that the surfaces are smooth, the polished edges are round, and the design is appropriately nuanced – the benefits of acrylic bending and molding utilizing laser machines are truly incomparable.

Advantages of Acrylic laser cutting

The Laser Machines for acrylic cutting and engraving procedures are gaining momentum due to a wide range of benefits as shown below.

• Safe and secure procedure

The process of using acrylic laser cutter machines is comparatively safer than the other conventional acrylic cutting techniques. The advantage of the latest acrylic plastic or acrylic material laser cutting machines is that they don’t ask for fastening or aligning the acrylic material before cutting. Also, most of these laser cutting devices don’t need human intervention except for inspections and repairs. Therefore, it lowers the tendency of injuries to a significant extent.

• The efficient and convenient cutting procedure

Another excellent benefit of this acrylic laser cutting procedure is that it offers high-quality performance, maximum speed and reliability, and ensures good quality end products such as fine acrylic sheets. The efficiency and convenience obtained from these laser cutting techniques are extremely beneficial because all the parameters are computerized. Therefore, it reduces labor and increases the amount of precision in the work. Additionally, the use of laser cutter and laser engraver is incredibly profitable when compared to glass and other materials.

• Increased Productivity and fast outcome

It offers high throughput, high productivity, and fast speed. With the effective production of high throughput acrylic projects within a short time, you can earn a high turnover. The acrylic cutting and engraving process with a laser machine is always time and cost-effective when compared to the other methods.

• Maximum precision

It increases the optimum acrylic cutting precision and is helpful to detect the registration marks. For instance, if you are engaged in making acrylic furniture, like an acrylic table or need precise cut- acrylic designs for acrylic lighting fixtures, then these machines are highly useful to automatically regulate the laser positioning. Hence, you can obtain high accuracy with a sharp laser cut of the acrylic material.

• Flexibility

There are several products you can build-out of the versatility and durability of acrylic. For instance, the requirement for products like acrylic roofing sheets, Acrylic Plexiglas, and acrylic panels, have been high, and the demand for acrylic engraving service in UAE has seen a huge upsurge since they are efficient, flexible, and economically viable.

Methods of Laser Cutting Acrylic

When you consider acrylic laser cutting, there are various aspects that define the method you have to choose for the cutting process. The material, machine, and design are these core aspects to be considered while deciding on the method. Let’s now take a look at these methods.

• Acrylic Laser Cut Designs

When you wish to make some particular shapes out of the acrylic material you use, the common method adopted is to have laser-cut designs. These designs can have any shape as per your requirement. This is usually achieved with an exact laser-cut derived from a whole laser sheet or a laser material. The laser-cut designs are made more creative with the help of computer software and CAD designs to get more attractive shapes of acrylic.

• Reactive Cutting Acrylic Sheet

Reactive cutting is also known as burning stabilized acrylic cutting or flame cutting. It is similar to a technique where the laser beam is used as the ignition source to cut materials with thicknesses of more than 1mm. With less laser power, you can cut relatively thicker acrylic sheets.

• Melt and Blow Acrylic Sheet

The melt and blow acrylic sheet method is also called a fusion acrylic cutting method. The method uses a high-pressure gas jet that blows the molten substance from the kerf in order to manage the temperature of the substance.

• Vaporization Cutting Acrylic Sheet

In this cutting, the focused beam heats up the acrylic surface up to the boiling point once it produces a keyhole. With improved absorptivity, the hole is further deepened. It then generates vapor after intense boiling of the material. The vapor pressure lets it erode the melt material and blows it out increasing the keyhole size. This is one of the ideal acrylic cutting methods.

• Thermal Stress Cracking Acrylic Sheet

Since acrylic is brittle, it is also highly sensitive to thermal fracture. Thermal acrylic cutting includes the utilization of beams focused on the material surface, which is then resulted in localized heating techniques to result in thermal expansion. By moving the beam, it results in moving the crack in m/s order.

The basic safety measures to be taken for acrylic laser cutting

Various laser products require different types of shapes which you can obtain with laser cutting. It is necessary to understand the fabrication needs and create patterns accordingly. Ensure that precautions are laid in place throughout the fabrication process.

Generally, acrylic bending and acrylic polishing offer a fairly sleeker look that results in supreme-quality products that seem to be quite attractive to the customers. Therefore, acrylic design is the best option to create smooth, complicated pieces from a durable material. Moreover, nowadays, numerous Acrylic fabricators in Dubai choose laser technology because it helps them to create better acrylic products in less time.

It’s important to understand that creating patterns by utilizing acrylic material requires careful observation and understanding of various precautionary measures. Here are the safety precautions to be taken before and after acrylic fabrication:

Ⅰ. Prevention of burns in the course of acrylic laser cutting

This is mainly focused on novices but applicable to everyone involved in laser cutting, since it is important to wear protective gear like gloves to avoid accidental events. During the heating process, certain hot pieces of the material might fall on the skin. Once fallen, these materials are impossible to remove and cause permanent harm to the body. Additionally, the temperature of the cutting machine must be well maintained, and regulate the heat to prevent burns.

Ⅱ. Appropriate comprehension of acrylic laser cutting procedures

To get the perfect outcome, knowing all the steps involved in manufacturing acrylic products is necessary. It also helps to prevent numerous risks and make you aware of how acrylic laser cutting machines operate and the working processes. Non-Metallic Materials like acrylic are expensive products. Hence, it is important to have an appropriate understanding of the method to ensure minimum wastage of the acrylic material.

Ⅲ. Efficient dealing with the fumes of acrylic laser cutting machines

Since laser cutting requires extremely high temperatures, the heat would cause the acrylic material to produce a huge amount of fumes. While cutting the acrylic, if someone is in close contact with this fume, it can be dangerous to health. Even the fumes can cause the creation of irregular shapes of acrylic products. That’s why the acrylic laser cutting companies ensure that the workers wear protective gear during the acrylic cutting or acrylic bending projects.

Ⅳ. Settings of the laser cutting machine

To get the best outcome, it’s essential to understand the operating procedures of a particular acrylic Plexiglas cutting machine. As different machines have different features, and the settings are different based on the frequency, speed, and power, therefore adjusting the parameters appropriately is the best way to achieve supreme-quality outcomes.

Ⅴ. Type of the acrylic laser cutter

Before starting to use a machine like a Laser Engraver, it’s important to know the machine’s Mechanical Properties, efficiency, performance, and applications. Also, there are some laser cutting machines that are attributed to a specific type of acrylic material. Therefore, to make sure that the machine actually serves the intended needs, all the technical features and parameters should be checked.

Ⅵ. Speed of functioning

The laser cutting machines offer a wide range of speeds of functioning. Also, there’s a particular cutting speed chart to ensure specific products’ proper cutting and engraving. Moreover, it would help in cutting out particular shapes and acrylic Engraving patterns and creating products like Acrylic Business Card holder quickly. The velocity of the machine’s operation involves concentrating the beam on the surface of the acry lic material. As the acrylic materials are relatively brittle and are sensitive to high speed, adjusting the machine’s speed is necessary.

Conclusion

You can source the best quality acrylic sheets for developing the laser cut products from the Acrylic sheet supplier in Dubai. Acrylic laser cutting and acrylic engraving process are highly growing due to the extreme durability and affordability of acrylic products. Apart from these properties, there are varieties of acrylic products in the market, like the trending acrylic nail kit, acrylic display, acrylic aquarium, acrylic roofing sheet, and acrylic cosmetic box in Dubai. Laser cutting is a widely accepted technique by most of the businesses to deliver top acrylic product designs, and make it creative to attract the customers.

FAQ – Frequently Asked Questions

ⅰ. Why should I buy a laser for acrylic cutting?

An acrylic laser cutting machine is extremely beneficial because it offers –

- No requirement to modify or replace tooling, lower lead times, and lower costs.

- Higher utilization of the material and less wastage

- High precision and security cuts

- Handling tasks of any complexity

- A varied range of cutting versatility

ⅱ. How thick of acrylic can you laser cut?

PMMA or acrylic is perfect to design the laser processing projects using acrylic ideas, particularly, the POS acrylic display, signage, illuminated advertisements, acrylic display stand, acrylic panels, etc. Laser cuts can make the edges shiny and polished. Acrylic up to 25mm thickness can be cut with lasers efficiently. Using CO2 laser, acrylic can be engraved or marked to make color changes using fiber laser. Acrylic cutting, bending, and engraving have been widely adopted by acrylic laser cutting companies to create amazing acrylic cut designs.

ⅲ. How do you laser engrave acrylic?

Firstly, you will have to make sure that the acrylic material is devoid of cracks and scratches. Next, you have to focus the beam of the laser on the acrylic material by maintaining its power and speed. Then, after the engraving is done, the material must be left aside for some time for cooling. And lastly, you have to remove the remaining melted acrylic by using water and soap.