What are the Advantages of Acrylic Plastic

There are several important uses of Acrylics. That is because this material has powerful advantages. But it is time you knew some other advantages of acrylic plastic. In this post, we will introduce you to the world of these benefits and advantages of acrylic plastic.

Advantages of Acrylic Plastic

1. Better than Waste Wood

Some say acrylics aren’t recyclable. In terms of this disadvantage, it is usually tallied by other useful benefits. As acrylic can be used in place of wood, acrylic furniture is growing concept. Wood has become scarce and cutting them down can be highly dangerous for the environment. Wood is also having poor disposal where it gets burnt after throwing them away. The smoke from huge waste wood burning can cause an unwanted increase in harmful gases. Whereas Acrylic doesn’t get burnt after disposal. Moreover, the acrylic has more life and does not need to be thrown away. In terms of environment, acrylic is better than wood and natural substances. It is less harmful than waste wood.

2. Simple to Fabricate and Shape

After this material reaches a hundred degrees you can mould it into a useful shape. Here are a few of the forms that you can mould them:

- Bottle

- Tube

- Photograph frame

- Painting frame

- Figurine

When the material gets cooled it retains the form of the mould without much effort. In this manner, you can create forms of the big sheet. Such a sheet will make any bow-new aquarium as well as a skylight. After moulding, you can machine, drill and saw this substance similar to softer metal and wood.

To create those forms you can use a mould that is made of plastics and wooden substances. In this way, the manufacturer saves a lot of cash. By the sixties, a designer started to use acrylic to create furniture. Even guitars are crafted using this superb material. Denture sets are also created using this type of plastic.

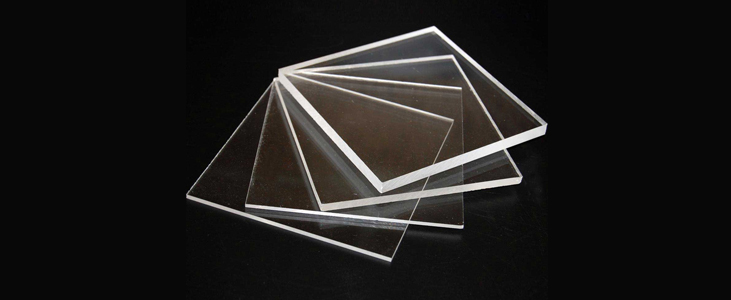

3. Stronger than Glass

This plastic derivative is the strong transparent substance. Now you do not need to use glass. Glass is brittle and heavy. Upon breaking it can fall on people and create serious injuries. But plexiglass or acrylic is not like that. This material first was known as plexiglass. It means you can use it wherever you use glass. Several terms denote acrylics. The many terms of this superior material are Lucite’s, Optix’s as well as acrylic-glass. However, you will be surprised to know that the chemical arrangement is only one. Aren’t these properties of acrylic plastic pleasantly surprising?

In terms of chemical angle, this substance is the synthetic polymer called polymethyl methacrylate, as well as PMM-A. In wars, many items used glass before. But once acrylics came into the picture there was no looking at the broken or shattered glass. That is the power of acrylics. They are powerful plus prevent any shattering. Hence several items need acrylics in wars. These items are the periscope, canopy as well as gun-turret. Furthermore, it finds useful application for a big aquarium-tank, protective cover in the ice-rink, forklift-guard, helmet-visor as well as the port that is used for watching in the submarine.

4. Resists Bad Weather & Maintains Colour

Do you know that Acrylic is quite tough? In this way, it can be used for creating beautiful windows at your home. In the same manner, you can create lenses for the headlight of the car. Moreover, the colour of the material will not change. Hence all the letters in your shop or company’s signboard will look fresh for years and decades. It happens because the substance resists any chemical change from the atmosphere or dust or water. The colours remain attractive.

The light rays from other sources cannot affect this material. And the colour remains the same. If you want any artwork or wall sign to get superb lighting inside a room then use acrylic. That is because the material is clear. It also refracts light in the right blend. Thus the artist for glass and the sculptor finds this material fascinating plus protected from the weather.

5. Light in Weight

When compared to glass this material is only half its weight. Such a light-weight aspect helps us to use the material in simple ways. You can see a light shoe, denture, as well as an artificial nail set. These sets are easy to use because of the lightness.

This polymer is light-weight. Do you know that a major portion of the composite in the dental filling is created from acrylics? Hence the area of cosmetic-surgery uses this plastic properly. Here small micro-spheres from acrylic types as the liquid is placed below the skin. Such procedures lessen any scar as well as wrinkle forever. Some homes need a skylight to get proper light in dark unventilated rooms. Because the material is lightweight the home foundations and frames will not get affected by any unwanted weight.

6. Impact Resistance

The tensility of acrylic is higher than ten thousand lbs. That is true for every square-inch. When compared to normal glass the impact resistance multiplies 5 or 16 more than ordinary glass. When a great impact happens, the material will prevent its shattering. Even by other means if the material disintegrates you only get big, dull-cornered pieces. In places where convicts or mentally ill patients stay, high impact resistance is needed for the barrier. These are used in the shower door, bath enclosure, sliding glass door as well as the security barrier of such places. Moreover in sports, you can see them in safety enclosure of the hockey rink as well as a ball field.

7. Great Transparence

The material acrylic keeps the optical clarity plus the thing doesn’t become yellowish with years of usage. Thus it has excellent transparency power. Such power helps in creating crucial parts like an aeroplane window, greenhouse, skylight as well as the store-in-front window. Besides, the material is useful in making surveillance-mirror as well as any window that needs to be highly durable.

The material can resist the ultraviolet ray from the sunlight. In this angle, people include the coating of acrylic on the sign, motorcycle cover as well as the external window. This material is best for food counters at the cafeteria, self-service salad-bar as well as grocery-stores that have the taken out display. Hence, when someone sneezes the food doesn’t get any of that sneeze.

Hope we answered some of your doubts through these recurring posts. Now you know some things about the advantages of acrylic plastic. Besides these applications of acrylic plastic can help you to improve your business significantly.

Pleasant Acrylic is an acrylic manufacturing company that provides acrylic service and fabrication in Dubai, United Arab Emirates, specializing in POP exhibits. The group is run by a leadership team with the aim of capturing the large acrylic market in the UAE through service excellence, service, good Acrylic Design UAE, and excellent satisfaction. For more details contact us today.

Frequently Asked Questions

1. Acrylic plastic vs. glass: what’s the difference?

The weight and unwieldiness of glass are well known. As well as being expensive, it is usually difficult to find. The iPhone, for example, contains a heavy glass (Gorilla glass) that makes it a heavy and expensive phone. The screen displays of many low-end phones are made of acrylic plastic, which is lighter than glass.

The flexibility of acrylic plastic is certainly greater than that of glass, and it is certainly more affordable. What does this mean in terms of efficiency? It’s not necessary. There are trade-offs when it comes to acrylic especially when it comes to phones, since it will likely scratch more than a glass display. However, the cost efficiency, benefits, and design options generally make it worthwhile.

Compared to glass, here are some key advantages:

✱ A lightweight material, acrylic weighs half as much as glass

✱ Durable and scratch-resistant

✱ In comparison to glass, the manufacturing process is simpler.

✱ Ten to twenty times stronger than glass in terms of impact resistance

✱ Skylights are perfect for acrylic because it is more insulating than glass

2. Are acrylic plastics BPA-free?

When deciding which plastic to use for building projects or manufacturing for different applications, many people look for plastics that do not contain Bisphenol A (BPA). Acrylic is a BPA-free alternative to polycarbonate that is not toxic when it is finished. Injection moulding, for instance, can emit fumes during the manufacturing process, but protective gear should be worn in any manufacturing environment, and the final product and form are safe for consumers.

3. Plastic made from acrylic is toxic, isn’t it?

In its final form, it does not contain any toxic chemicals. It does, however, emit some fumes during the manufacturing process, though not on the same level as many other materials. Once it is in its final form, acrylic contains no harmful chemicals and produces little fumes during production. According to OSHA regulations, it is not a hazardous material.

4. When acrylic is exposed to the sun, does it yellow?

It is not possible for acrylic to yellow in the sun. As a natural gas product, it won’t discolor. A few plastics are resistant to UV light, including acrylic. Because of this, it makes an excellent shed window material and skylight or panel material for your home projects without the worry of discoloration.