When it comes to reflecting surfaces, two primary contenders emerge ie., acrylic and glass mirrors. While both serve the same fundamental purpose, they differ significantly in composition, properties, and applications. Understanding these distinctions is crucial for selecting the most suitable option for your needs. In this blog, we’ll delve into the nuances between acrylic and mirrored glass, exploring factors such as durability, installation, safety considerations, environmental impact, and suitability for various applications. By the end, you’ll have a comprehensive understanding of these mirror types, acrylic vs glass, empowering you to make informed decisions for your projects or spaces.

Table of Content

Differences Between Acrylic Mirrors and Glass Mirrors

Composition and Properties

A. Composition of Acrylic Mirror

Description of Acrylic Material:

- Acrylic, also known as polymethyl methacrylate (PMMA), is a transparent thermoplastic that exhibits glass-like properties. It is derived from acrylic acid and is commonly used as a lightweight alternative to glass. Acrylic boasts excellent optical clarity and is available in various thicknesses and colors, making it versatile for different applications.

Manufacturing Process

The manufacturing process of acrylic mirrors involves several steps:

- Extrusion: Acrylic pellets are melted and extruded into sheets of desired thickness.

- Cooling and Cutting: The extruded acrylic sheets are cooled and then cut into specific sizes.

- Polishing: The cut sheets undergo polishing to achieve a smooth and reflective surface.

- Coating: A reflective coating, typically aluminum or silver, is applied to the back surface of the acrylic sheet to create the mirror effect.

- Protective Layer: A protective film may be added to the front surface to prevent scratches and damage during handling and installation. Dealers of acrylic plastic UAE then supply these products to acrylic product manufacturers.

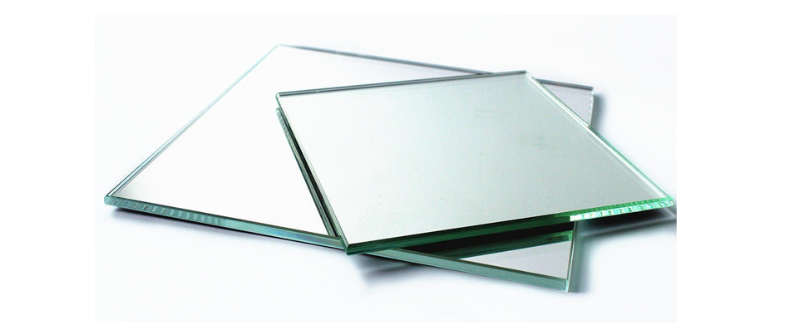

B. Composition of Glass Mirror

Description of Glass Material:

- Glass mirrors are made from a sheet of glass that has been coated with a reflective material, typically silver or aluminum. Glass mirrors have been widely used for centuries due to their exceptional clarity and reflective properties. They are available in various thicknesses and can be customized to different shapes and sizes.

Manufacturing Process

The manufacturing process of glass mirrors involves the following steps:

- Glass Cutting: Large sheets of glass are cut into desired sizes using cutting machines or tools.

- Cleaning: The glass sheets undergo thorough cleaning to remove any dirt or impurities.

- Coating Application: A thin layer of reflective material, such as silver or aluminum, is applied to one side of the glass sheet using a vacuum deposition process.

- Protective Backing: A protective backing, usually made of paint or other materials, is applied to the back of the mirror to prevent corrosion and damage to the reflective coating.

- Quality Control: The mirrors undergo quality control checks to ensure uniformity and clarity of reflection.

C. Properties Comparison

- Weight:

- Acrylic Mirror: Acrylic mirrors are significantly lighter than glass mirrors of comparable size. This makes them easier to handle and install, especially in applications where weight is a concern. Acrylic sheet suppliers in Dubai can keep and transport bulk quantities easily due to this lightweight property.

- Glass Mirror: Glass mirrors are heavier than acrylic mirrors, which can pose challenges during transportation, handling, and installation.

- Durability:

- Acrylic Mirror: Acrylic mirrors are more impact-resistant than glass mirrors and are less likely to shatter upon impact. However, they are prone to scratching and may require special care to maintain their appearance. Acrylic glass suppliers in Dubai can stock large quantities for a long time due to its durability. Acrylic brochure stand suppliers in Dubai say that due to this property, the demand for acrylic podiums in Dubai and stands are growing.

- Glass Mirror: Glass mirrors are more susceptible to breakage and shattering compared to acrylic mirrors. However, they are more scratch-resistant and can withstand cleaning with harsher chemicals.

- Clarity and Reflection Quality: Acrylic mirrors may exhibit slight distortions and lower clarity compared to glass mirrors. However, advancements in manufacturing techniques have led to improved clarity in acrylic mirrors. However, when compared to plastic fabrication in Dubai, acrylic glass is the best. You can check out the tips for working with acrylic to make cost-effective products where the clarity of the glass feature is not an issue.

- Cost:

- Acrylic Mirror: Acrylic mirrors are generally more affordable than glass mirrors, making them a cost-effective option for budget-conscious projects. Hence, the beauty product and ornament industry is using acrylic cosmetic boxes in Dubai for displaying the products.

- Glass Mirror: Glass mirrors tend to be more expensive than acrylic mirrors due to the higher cost of materials and manufacturing processes involved.

Installation and Maintenance

A. Installation Process for Acrylic Mirrors

Advantages:

- Lightweight: Acrylic mirrors are lighter than glass mirrors, making them easier to handle and install, especially in overhead or wall-mounted applications like acrylic wall mirrors. .

- Flexibility: Acrylic mirrors can be easily cut and shaped using standard tools, allowing for customization to fit specific spaces or designs.

- Adhesive Mounting: Acrylic mirrors can be mounted using adhesive tapes or silicone adhesives, eliminating the need for drilling and reducing the risk of damage to surfaces.

Precautions:

B. Installation Process for Glass Mirrors

Advantages:

- High Clarity: Glass mirrors offer superior clarity and reflection quality compared to acrylic mirrors, providing a more precise and distortion-free reflection.

- Rigidity: Glass mirrors are rigid and less prone to warping or distortion, providing a stable and durable surface for installation.

- Traditional Mounting Methods: Glass mirrors can be installed using traditional methods such as screws, clips, or mirror mastic, providing a secure and long-lasting attachment.

Precautions:

- Safety Gear: Wear appropriate safety gear such as gloves and goggles when handling glass mirrors to prevent injury from sharp edges or broken glass.

- Secure Mounting: Ensure that glass mirrors are securely mounted using proper hardware and techniques to prevent accidents or injuries from falling mirrors.

- Professional Installation: Consider hiring professionals for the installation of large or heavy glass mirrors to ensure proper support and safety measures are implemented.

C. Maintenance Requirements

- Cleaning Methods:

- Acrylic Mirrors: Clean acrylic mirrors with a soft, non-abrasive cloth and mild soap or acrylic cleaner. Avoid using abrasive cleaners or rough materials that can scratch the surface. Acrylic Design Dubai companies provide various tips to maintain these acrylic products.

- Glass Mirrors: Glass mirrors can be cleaned using glass cleaner and a soft cloth or paper towel. Avoid using abrasive cleaners or harsh chemicals that can damage the reflective coating.

- Susceptibility to Scratches and Damage:

- Acrylic Mirrors: Acrylic mirrors are more susceptible to scratches and damage compared to glass mirrors. Handle with care and avoid contact with sharp objects or abrasive materials. Hence, acrylic laser cutting services in Dubai are used to cut acrylic glasses.

- Glass Mirrors: Glass mirrors are more scratch-resistant but can still be damaged if mishandled or cleaned improperly. Take precautions to avoid scratches and chips during installation and maintenance.

Safety Considerations

A. Breakage and Shattering

- Differences in Breakage: Acrylic mirrors are less likely to shatter upon impact compared to glass mirrors, which can break into sharp, dangerous shards.

- Safety Precautions: When installing mirrors, especially in high-traffic areas or environments with children or pets, ensure proper support and use safety backing or adhesive to prevent injuries from broken glass shards.

B. Fire Hazards

- Response to Heat and Flames: Acrylic mirrors are more heat-resistant than glass mirrors and may melt or deform under extreme heat, while glass mirrors can withstand higher temperatures without melting. Acrylic signage board suppliers in Dubai say that this factor has led to a very high growing demand for signage boards for outdoor displays.

- Safety Implications: In fire-prone areas, consider the heat resistance of mirrors and their proximity to potential sources of ignition to minimize fire hazards and ensure occupants’ safety.

Application and Suitability

A. Indoor vs. Outdoor Use

- Weather Resistance: Acrylic mirrors are generally more suitable for outdoor use due to their weather-resistant properties, as they are less prone to damage from moisture, humidity, and temperature fluctuations compared to glass mirrors.

- UV Stability: Acrylic mirrors offer better UV stability than glass mirrors, making them ideal for outdoor applications where prolonged exposure to sunlight may cause fading or degradation of reflective properties.

B. Commercial vs. Residential Applications

- Considerations for Different Settings: Commercial settings may require larger, more durable mirrors to withstand heavy use and potential impact, while residential applications may prioritize aesthetics and customization options.

- Suitability for Various Purposes: Both acrylic and glass mirrors are suitable for a wide range of purposes, including décor, safety (e.g., mirrors in gyms or public spaces), and aesthetics (e.g., decorative mirrors in homes or retail spaces). Consider the specific requirements and design preferences of each application when choosing between acrylic and glass mirrors.

Conclusion

Acrylic mirrors offer lightweight and impact-resistant alternatives to glass mirrors, while glass mirrors provide superior clarity and durability. Acrylic mirrors are more suitable for outdoor use and offer better UV stability, whereas glass mirrors are often preferred for their high clarity and reflective quality. When selecting between acrylic and glass mirrors, consider factors such as application (indoor vs. outdoor), durability, clarity, and budget to meet specific needs effectively.

Demand for Acrylic UV printing services in Dubai is increasing especially during events held in Dubai. Ultimately, the choice between acrylic and glass mirrors depends on individual requirements and preferences. By weighing the advantages and limitations of each type, you can make an informed decision to achieve optimal results in your projects or spaces.

also read: Acrylic vs Plexiglass: A Detailed Comparison