In the realm of versatile construction materials, acrylic sheets stand out for their unique properties. Acrylic, a transparent thermoplastic, is widely recognized for various applications from signage to protective barriers. Here, in this blog, we discuss regarding durability of thick acrylic sheets and also explore their strength. These robust variants play a pivotal role in diverse applications, emphasizing the significance of durability in ensuring longevity and reliability.

Table of Content

How Strong is Plexiglass?

Plexiglass, a brand name for acrylic glass, exhibits remarkable strength. Renowned for its impact resistance, it surpasses traditional glass in durability. The material’s strength lies in its ability to withstand external forces, making it a preferred choice for applications where resilience is paramount. Whether in protective barriers, automotive components, or artistic installations, plexiglass proves its mettle by maintaining structural integrity even in challenging environments. Its strength, coupled with transparency and versatility, positions plexiglass as a reliable and robust material across various industries.

How Strong is Acrylic?

Acrylic, a thermoplastic polymer, boasts impressive strength across a spectrum of applications. Known for its resilience and impact resistance, acrylic demonstrates strength comparable to glass but with added advantages. Its durability is evident in diverse settings, from architectural glazing to intricate artwork. Acrylic’s strength is further enhanced by its lightweight nature, making it a practical choice for situations where a balance of strength and manoeuvrability is crucial. Whether in construction, automotive design, or creative projects, acrylic stands as a testament to the enduring strength of modern polymers in a multitude of scenarios. Is acrylic strong is no more a concern from the provided data.

Factors Influencing Durability of Acrylic Sheets: Unveiling the Strength

Acrylic sheets’ durability is a key factor in their widespread use, influenced by various factors that contribute to their robustness. Understanding these factors is crucial for appreciating the exceptional strength that acrylic exhibits in diverse applications.

Chemical Resistance

How Acrylic Reacts to Different Chemicals

Acrylic’s notable chemical resistance is a testament to its durability. Unlike some materials that succumb to corrosive substances, acrylic maintains its structural integrity when exposed to a range of chemicals. This resistance extends to acids, alkalis, and solvents, making acrylic sheets suitable for environments where chemical interactions are prevalent. This is highly beneficial for acrylic signage board suppliers in Dubai since they don’t have to take many precautions.

Applications Requiring Chemical Resistance

Industries such as laboratories, manufacturing, acrylic UV printing services in Dubai and healthcare benefit from acrylic’s chemical resistance. In laboratories, where exposure to various chemicals is routine, acrylic proves indispensable for creating durable and transparent barriers. Its resilience to chemical wear ensures a longer lifespan, making it a preferred choice in settings demanding both clarity and durability.

Impact Resistance

Testing Methods for Impact Resistance

Acrylic’s strength is thoroughly tested through impact resistance assessments. Various standardized methods, such as falling weight and pendulum impact tests, gauge the material’s ability to withstand sudden forces. These tests ensure that acrylic sheets meet stringent criteria for impact resistance, guaranteeing their reliability in real-world scenarios.

Real-World Scenarios Showcasing Impact Durability

Acrylic sheets excel in real-world applications where impact durability is paramount. From protective barriers in sports arenas to transparent shields on manufacturing floors, acrylic’s ability to absorb and disperse impact forces is evident. This property is particularly crucial in automotive applications, where acrylic windows demonstrate resilience against road debris and potential collisions. Acrylic sheet suppliers in Dubai is having a great time in business owing to the demand for thick acrylic sheet.

Environmental Factors: Nurturing Acrylic Resilience

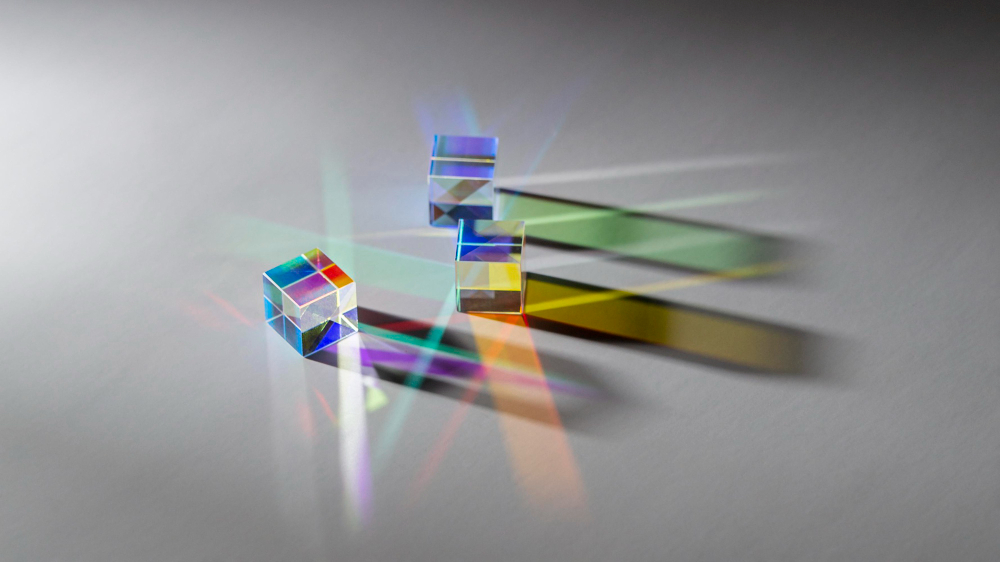

UV Resistance

Importance of UV Resistance in Outdoor Applications

UV resistance is paramount for acrylic sheets used in outdoor settings. Prolonged exposure to sunlight can lead to material degradation, discolouration, and reduced transparency. Acrylic’s inherent UV resistance ensures that it can withstand the harsh effects of the sun, maintaining its optical clarity and structural integrity over time.

Effects of Prolonged Sun Exposure on Acrylic

Without adequate UV resistance, acrylic may suffer from yellowing and surface deterioration when exposed to sunlight. This makes UV-resistant acrylic an ideal choice for applications such as outdoor signage, windows, and protective enclosures, where the material must endure continuous exposure to the sun without compromising its visual and structural qualities. This feature is beneficial, especially in acrylic name board when fastened to walls exposed to UV light.

Temperature Resistance

Acrylic’s Performance in Extreme Temperatures

Acrylic exhibits remarkable temperature resistance, performing well in both hot and cold environments. Unlike some materials that may become brittle in extreme cold or soft in intense heat, acrylic maintains its flexibility and strength across a wide temperature range.

Applications in Hot and Cold Environments

This versatility in temperature resistance makes acrylic suitable for various applications. From skylights in hot climates to protective glazing in cold regions, acrylic’s stable performance ensures that it remains reliable and functional even in the face of extreme temperature fluctuations. This adaptability positions acrylic as a dependable material for diverse environmental conditions.

Scratch Resistance: Preserving the Pristine Appearance of Acrylic

Evaluating the Scratch Resistance of Acrylic

Assessing the scratch resistance of acrylic is crucial for applications where maintaining a pristine appearance is paramount. Whether used for Plastic fabrication in Dubai understanding how well acrylic withstands abrasion ensures longevity and visual appeal.

Protective Coatings and Treatments

To enhance scratch resistance, acrylic surfaces can be treated with protective coatings. These coatings act as a barrier, shielding the material from minor scratches and abrasions. For acrylic Podium in Dubai, where a polished appearance is essential, these coatings contribute to overall durability and aesthetic longevity.

Maintaining the Aesthetic Appeal Over Time

Regular maintenance, including gentle cleaning and avoiding abrasive materials, is key to preserving the aesthetic appeal of acrylic. This diligence ensures that Acrylic Cosmetic Box In Dubai maintain their clarity and visual allure, standing as durable and scratch-resistant fixtures in various settings. Before learning how to make acrylic boxes, these

Applications and Industries: Harnessing the Durability of Acrylic

Architecture and Construction

Acrylic durability plays a vital role in architecture and construction. Whether used for transparent barriers, skylights, or decorative elements, acrylic provides structural integrity while allowing natural light. Acrylic’s versatility also makes it a preferred choice for architectural models and intricate designs. Acrylic laser cutting services in Dubai facilitate precise customization, contributing to the aesthetic appeal of architectural features.

Automotive Industry

In the automotive sector, acrylic is employed for various applications, including windows, headlights, and interior components. Its impact resistance and optical clarity make it ideal for enhancing safety without compromising on design. Acrylic sheet suppliers in Dubai play a crucial role in providing materials that meet the stringent requirements of the automotive industry.

Signage and Display

Acrylic’s transparency and durability make it a staple in the signage and display industry. From illuminated signs to exhibition displays, acrylic design in Dubai offers a sleek and professional look. Acrylic UV printing services in Dubai allow for vibrant and long-lasting graphics, ensuring that signage remains eye-catching and resilient against environmental factors.

Medical Applications

In the medical field, acrylic is used for various applications such as medical equipment, laboratory enclosures, and protective barriers. Its chemical resistance and ease of sterilization make it a suitable material for creating hygienic and durable medical environments.

Other Niche Industries Benefiting from Acrylic’s Durability

Beyond mainstream applications, niche industries benefit from acrylic durability. This includes the production of intricate models in the manufacturing sector, artistic installations in the creative industry, and specialized equipment in research and development. Acrylic’s adaptability caters to the specific needs of these diverse industries, ensuring that the material remains a reliable choice in unique applications.

Future Trends: Advancements Shaping the Acrylic Landscape

Ongoing Research and Development in Acrylic Technology

Continuous research and development in acrylic technology pave the way for innovative applications. Dealers of acrylic plastic in UAE are at the forefront of adopting and implementing these advancements, ensuring that the material remains cutting-edge in terms of performance and versatility.

Emerging Applications and Industries Adopting Acrylic

As new possibilities unfold, emerging industries are increasingly turning to acrylic for its adaptability. Acrylic signage board suppliers in Dubai, for instance, are witnessing a surge in demand as the material finds novel applications in the ever-evolving landscape of visual communication.

Potential Improvements in Acrylic’s Durability

The future holds promise for enhanced durability in acrylic. Anticipated improvements may include advanced protective coatings and treatments, addressing specific industry needs. This continuous refinement ensures that acrylic maintains its position as a durable and sought-after material in various sectors.

Conclusion

The durability of acrylic sheets, highlighted through factors like chemical resistance, impact resilience, and environmental adaptability, underscores their strength in diverse applications. From crafting intricate designs to safeguarding against external forces, acrylic stands as a durable solution. The versatility of acrylic, showcased in applications like creating acrylic boxes, signages, and architectural features, reaffirms its significance across industries. As technology advances and new applications emerge, the prospects for acrylic seem boundless, promising continued innovation and adaptation. To those seeking reliable and adaptable materials, encourage exploration into the world of acrylic. For acrylic podium suppliers in Dubai, acrylic’s durability and versatility make it an exciting and enduring choice for diverse creative and practical endeavours.